Introduction of wood sawdust pellet line

The wood sawdust pellet line is a whole system automatic production line which suitable for raw materials like: sawdust, rice husk, rice straw, cotton stalks, forest wood waste, wood waste and other biomass waste with different capacity.

Application of wood sawdust pellet line

Today, the biomass energy as a good kind of green, low carbon, environmental-friendly fuel has been used to replace traditional fossil fuels like coal, gas, petrol, etc.

1.Burning in a stove to cook at home;

2.Heat the house, school, hotel, or greenhouse, farm;

3.Used in thermal power plants to replace coal.

4.Used as cat litter to replace clay;

5.Used as horse bedding, or beddings for cow, chicken, dogs, and other animals.

Flowchart of wood sawdust pellet line

The wood sawdust production line includes material sieving, drying (if the raw material contains

too much moisture), wood pellets pelletizing, cooling, screening and packing.

Main process of wood sawdust pellet line

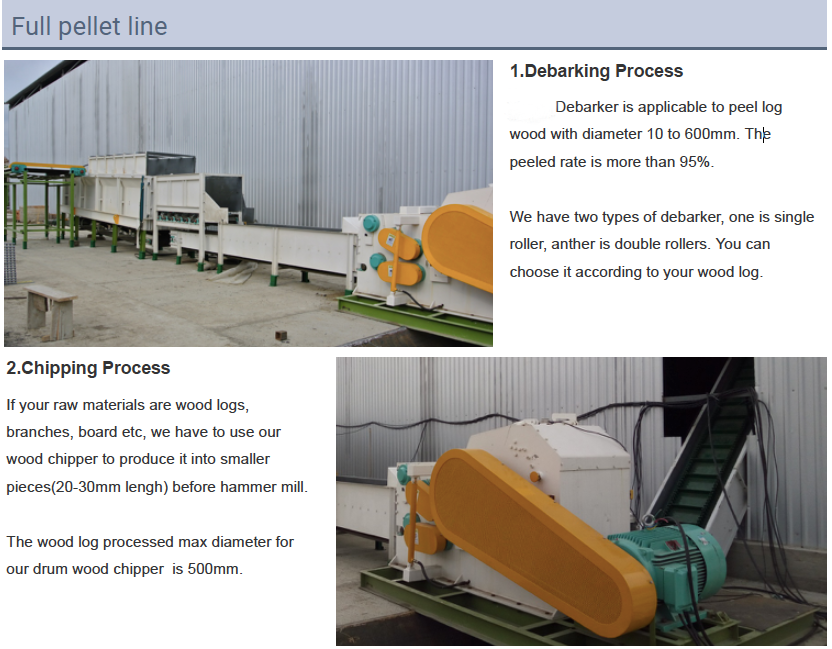

Pre-cleaning process - pre-cleaner

To remove the impurities in the raw materials such as stone or some too big materials.

Remark: This process is optional. If the raw material is clean, it is not necessary.

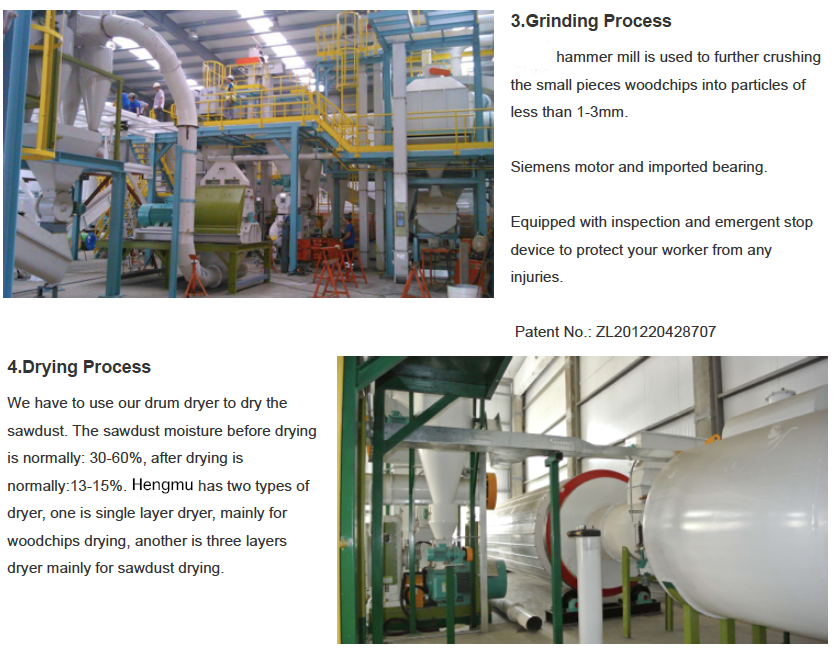

Drying process - Rotary Dryer

The best moisture content to pelletizing is about 12-18%. Our rotary dryer is made up of

burning stove and main rotary dryer which is high efficient in drying the wood and biomass

material. It can realize to reduce the moisture from 50% to 10%.It is very important for

wood pellet plant to using moisture detector which will determine the most suitable

moisture before pelletizing.

Pelletizing process - Wood pellet mill

Wood pellet mill is the heart of the wood pellet production line, and has reliable running

performance. It is special designed for compacting of wood, straw, and other biomass

sources into pellets. Capacity ranges from 1T to 10T per hour. Our SZLH series Ring die

pellet mill is best choice for large scale production.

Cooling process - Counterflow cooler

Usually after pelletizing, the temperature of wood pellets is between 60-80 degrees and

the moisture content is close to 15%. For storage purposes,a cooler must beused to

reduce their surface temperature and the moisture content, also help screen good and

pure pellets.

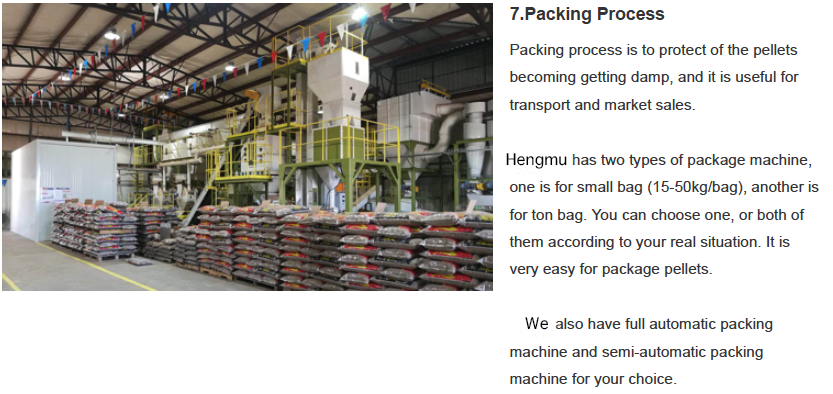

Packing process - Packing machine

After cooling process, the wood pellets will not directly enter into the fuel process, avoiding

the wood pellet affected with damp, the packing process is very necessary. The packing

process is effectively handled by our Semi-Auto Packing Machine.

Remark: We can customize the complete solution as per your raw materials condition and

your request for capacity.

Our service

As a professional and experienced supplier of turn-key projects in China, we have the ability

to provide full services for customers:

1. Complete project design

2. Equipment manufacture and project engineering

3. Machinery delivery service to most of the locations in the world

4. Plant installation and commissioning service

5. Staff training and project managements

6. Spare parts supply and lifelong consultation service

7. Possible financial and banking services for some projects