Welcome to HengMu machinery's guide on how to create exceptional wood pellets. As a leader in the industry, we are dedicated to providing high-quality and sustainable energy solutions. In this article, we will walk you through the step-by-step process of making superior wood pellets, highlighting our expertise and commitment to excellence.

Step 1: Selecting the Finest Wood Material

The foundation of our premium wood pellets lies in the selection of the right wood material. We carefully choose dry hardwoods such as oak, maple, and beech, known for their high energy content and low moisture levels. Our commitment to sustainable forestry practices ensures responsible sourcing, promoting environmental conservation.

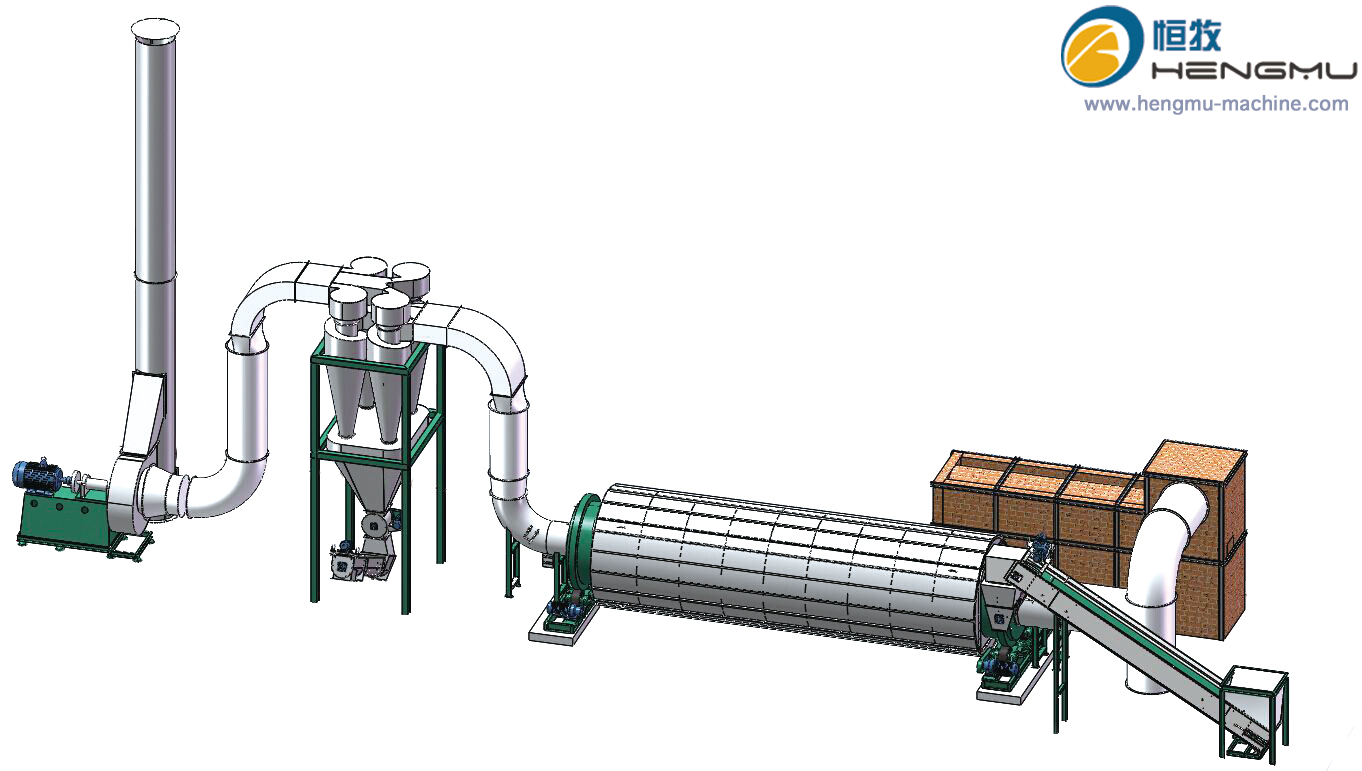

Step 2: Meticulous Wood Preparation and Drying

To guarantee the utmost quality, we meticulously prepare the wood before pelletizing. Our process involves debarking the logs and eliminating any impurities or contaminants. Proper drying is critical to reduce moisture content, enabling optimal combustion efficiency and pellet durability. We ensure a moisture level of approximately 10-15% for superior performance.

Step 3: Precise Grinding for Consistent Particle Size

Consistency in particle size is essential for creating high-quality wood pellets. Our state-of-the-art wood grinders or chippers guarantee uniformity, resulting in pellets that burn efficiently and provide consistent heat. This precision in grinding sets our pellets apart, delivering exceptional performance and customer satisfaction.

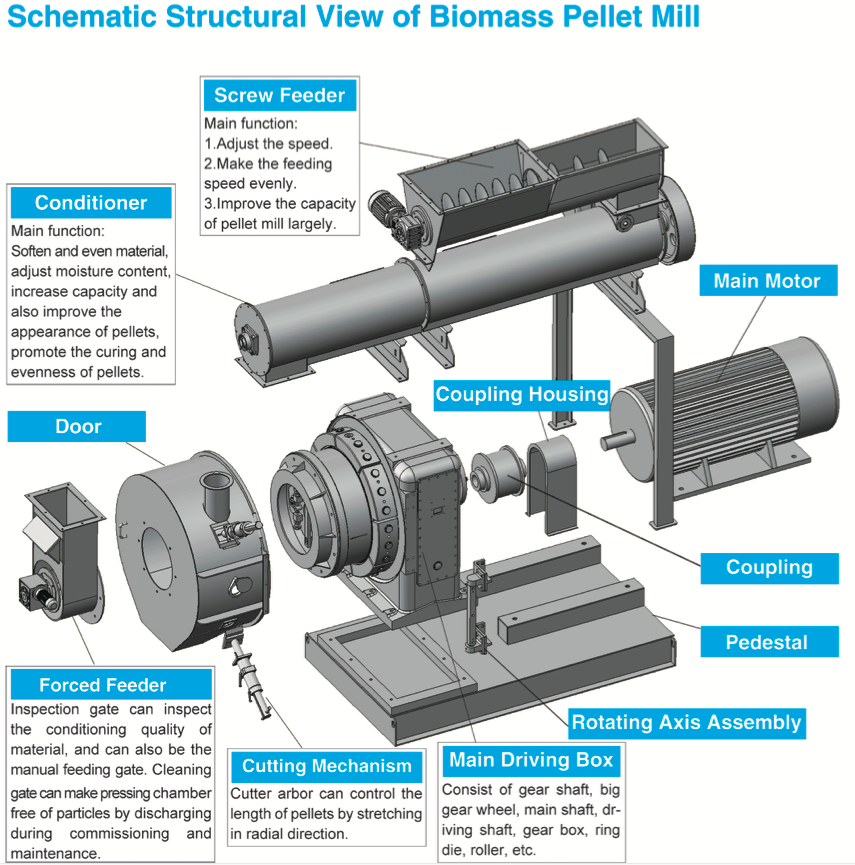

Step 4: Expert Pelletizing Process

Our expertise shines through in the pelletizing process. Utilizing cutting-edge pellet mills with the perfect die size, we ensure consistent pellet shape and size. By adjusting compression pressure, temperature, and moisture levels, we optimize pellet density and energy efficiency. This expertise translates into pellets that exceed industry standards.

Step 5: Thorough Cooling and Drying

After pelletizing, we subject our pellets to a meticulous cooling and drying process. This additional step reduces moisture content to approximately 8-10%, resulting in pellets that are stable and have an extended shelf life. Our commitment to quality extends beyond production to ensure our customers receive only the finest wood pellets.

Step 6: Stringent Quality Control Measures

At our company, quality control is of utmost importance. We implement stringent measures throughout the production process. Regular testing is conducted to assess factors such as moisture content, pellet density, and ash content. This rigorous quality control ensures that every pellet that leaves our facility meets the highest standards.

Step 7: Packaging and Storage Excellence

To maintain the quality of our wood pellets, we prioritize proper packaging and storage. Our durable, moisture-resistant bags or containers are meticulously sealed to protect against moisture and preserve the pellets' integrity. We store our pellets in a dry environment, safeguarding them from external elements. With our packaging and storage practices, we guarantee that our pellets arrive in optimal condition.

Conclusion:

Crafting superior wood pellets requires expertise, attention to detail, and a commitment to excellence. At our company, we pride ourselves on delivering exceptional products that exceed expectations. By following our step-by-step guide, we demonstrate our dedication to creating high-quality wood pellets that provide sustainable energy solutions. Choose our company for premium wood pellets that exemplify quality, performance, and environmental responsibility.