RING DIE FOR PELLET MILL MACHINE

Features

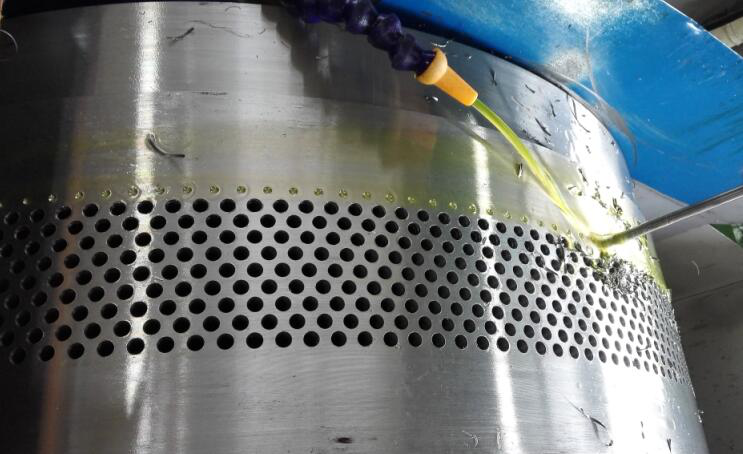

1.Advanced, automatic ring die processing technology: Full automatic CNC ring die drilling machine and vacuum heat treatment technology ensure the quality and working life of ring dies.

2.Rich ring die processing experience ensures the depth and opening ratio of the hole of ring die which can satisfy different requirements of shrimp feed, sinking fish feed, chicken feed, thus improves the pelleting efficiency.

3.The surface of ring die is of good smoothness, high hardness, and the pellets are of good shape and neat appearance.

4.Quick discharge, high output and the production efficiency of the same size are much higher than ring dies of other brands.

Vacuum heat treatment

1.Suitable hardening temperature of vacuum furnace ensures higher hardness and impact toughness.

2.Suitable drawing temperature ensures no cracks of ring dies and little wear of hole and surface, which improves the working life.

3.In same loading, adding backfill air pressure will boost die's cooling and hardness.

4.CNC control technology ensures the stability of ring dies.

Measurement of ring die dimension

1.Inspect the dimension of forging stock according to the order contract, measure with vernier caliper, and the deviation shall be less than ±1mm.

2.Based on the inner circle, rotating table and dial indicator shall be applied to inspect outer circle of forging stock and face run out, with deviation less than 1.0mm.

About Us:

Our pellet roller shell enjoy high abrasion resistance and corrosion resistance, which make sure roller get long service life.

We use high chrome stainless steel to make ring dies, and its hardness can reach HRC 52-56 after heat treatment.

We

can provide the roller parts for SZLH series pellet mill: such as

SZLH250, SZLH300,SZLH320,SZLH350,SZLH400,SZLH420,SZLH508 and so on.

For MZLH series pellet mill: such as MZLH420,MZLH508 and so on.

We also can make many famous models ring die & roller shells: such as:

CPM, Buhler, PTN, Andritz Sprout, Matador, Amandus Kahl, Muyang, Paladin, Sogem, Van Arssen, Yemmak, Promill; etc.

We make all kinds of pellet mill roller shells & ring dies according to customers' drawing.