【Applicatons】

Widely used in biomass-energy fuels plant, power plant, wood processing plant,fertilizer plant, chemical plant etc.

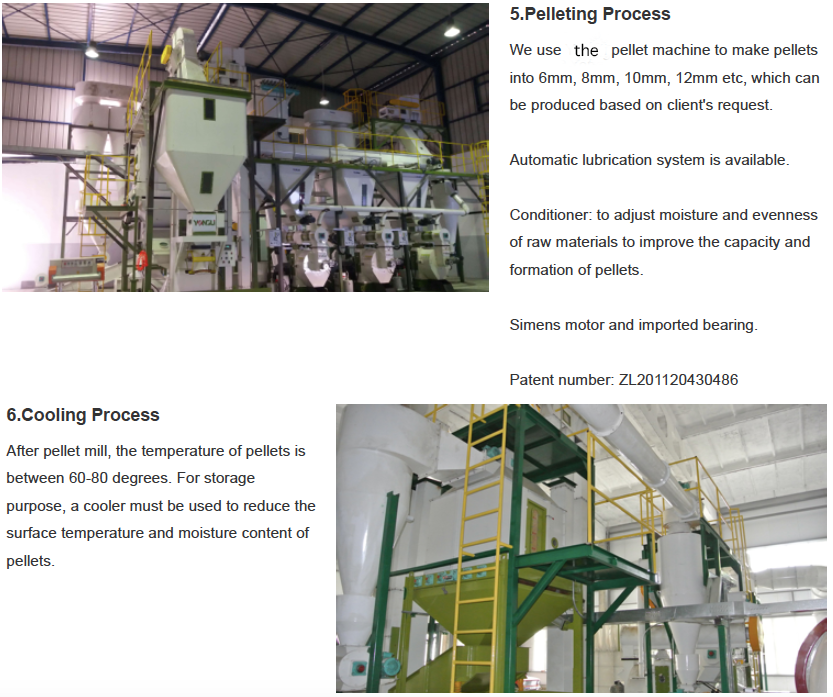

【Conditioner】

To adjust the moisture of the raw material.

To make the water and raw material mix evenly

To improve the capacity of the pellet mill.

Tips: For special materials, please contact us for better solution.

【Raw material】

Woodiness, straw, peanut shell, palm nut, coconut shell, cotton seed, bamboo dust, elephant grass, sugar cane,

pulp, olive slag, organic manure and so on.

【Working Principle】

Raw materials with water content no greater than 15% enter into screw feeder,the security magnetsremove the

magnetic impurity mingling with supplies, then through the en-forced feeder, enter the pressing room to pelletize finally.

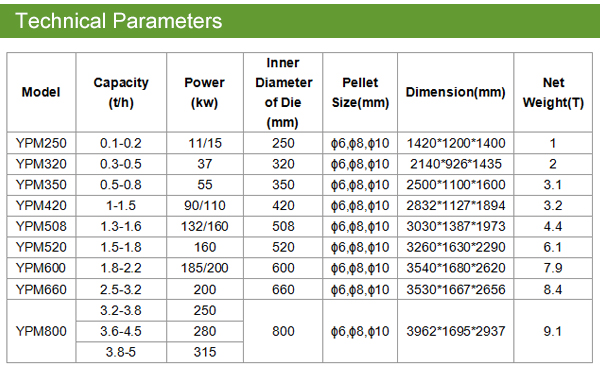

Tips: The type of pelletizer based on different capacity(t/h)

【Attractive advantages】

1.Non-dust workshop

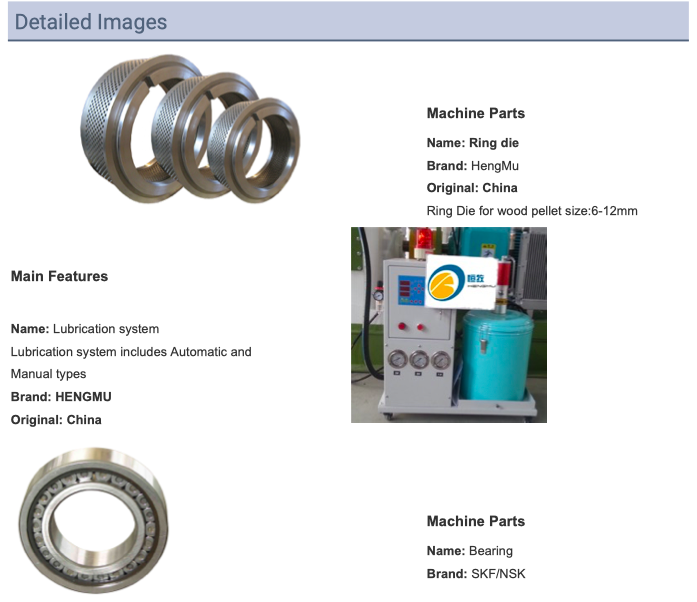

2.Siemens motor, Imported SKF/NSK bearing

3.Equiped with auto cooling and oil adding system

4.National patent

5.Lubrication system consists of automatic lubrication and manual lubrication.

6.Forced feeder: Forced feeding into pelletizing chamber, make pellet mill operate stable and with high efficiency.